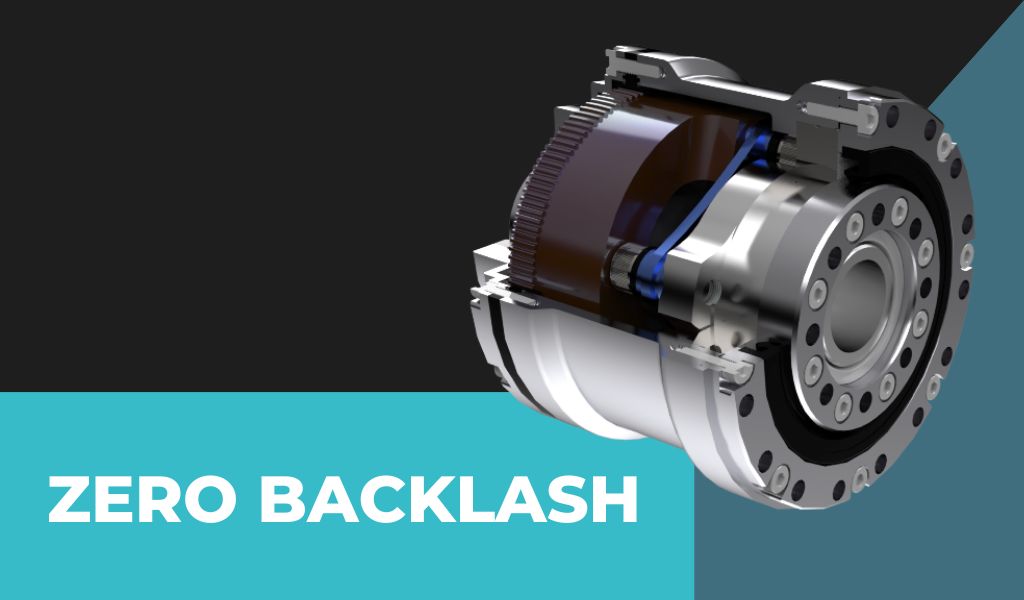

When robotics companies are looking for gear solutions for their robotic arms, they will often hear the zero backlash claim. But what exactly does that mean and why is it important? There are very distinct reasons for gear solution providers to work towards zero backlash in their engineering and development efforts. What it means to […]

Technical

Sierramotion Guest Post: What Coupling Should I Use?

There are many options to connect two rotating shafts together. The most obvious path is to use a rotary coupling. Unfortunately, while there are many couplings that can be purchased or made, choosing the right one takes some practice and a little bit of luck.

Video: Direct Drive Motors & Precision Gearing

Robots have evolved from moving big things around in large areas to working collaboratively with humans in tight or uncaged environments. Robot designers are continuously challenged to reduce motorized joints’ size and weight while improving accuracy and response. This recording will discuss how direct drive motors coupled to high ratio precision gearing are an excellent choice to meet these challenges.

Speed Reducers & Proper Shaft Alignment for Motion Control Applications

The selection of a proper coupling for a motion-control application requires consideration of numerous performance factors that must be taken into consideration for the coupling to work properly. These factors include including torque levels, the type and amount of shaft misalignment, inertia, torsional stiffness, rotational speed, space requirements, and others.

Torque Density Impacts Robot Speed

Humans know intuitively or from experience that if we put weights on our wrists or elbows, it becomes more difficult to move our arms. If we apply the same force we used without any weights, our arm will move more slowly.

It’s no surprise, then, that we see the same result in robots: as joints get heavier, the arm moves more slowly when the same force (or torque) is applied. Conversely, removing weight from the wrist or elbow actuator using a lighter weight transmission/gear drive results in higher speeds for the same applied torque.

What does a 10-15% increase in robot speed imply for robot owners?

Torque Density and Robot Reach

As we mentioned in the last post, we will be looking at how torque density influences different robot parameters, including reach, speed, and lifetime. Each of these in turn has a direct and important impact on the economic value of a robot to the end-user.

The Importance of Torque Density for Robot Performance

In the context of robotic actuators, the term torque density refers to how much torque the actuator is able to produce per unit weight or unit volume. The term can be applied to the actuator as a whole or separately to the motor or gearbox that is contained within the actuator. Why should we be interested in torque density? Because the torque densities of a robot’s components can limit nearly every facet of a robot’s performance.