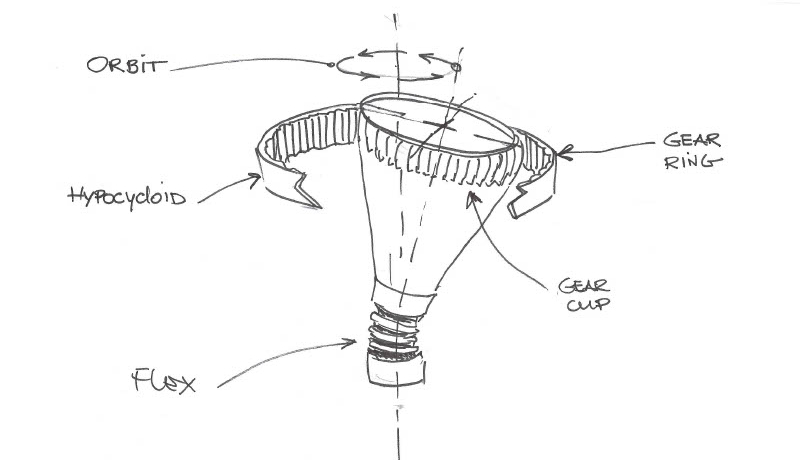

The design of Orbital Flex™ began when thinking of how a cylinder rolls inside a larger cylinder in an orbiting motion.

Motus Blog

Hexagon Case Study

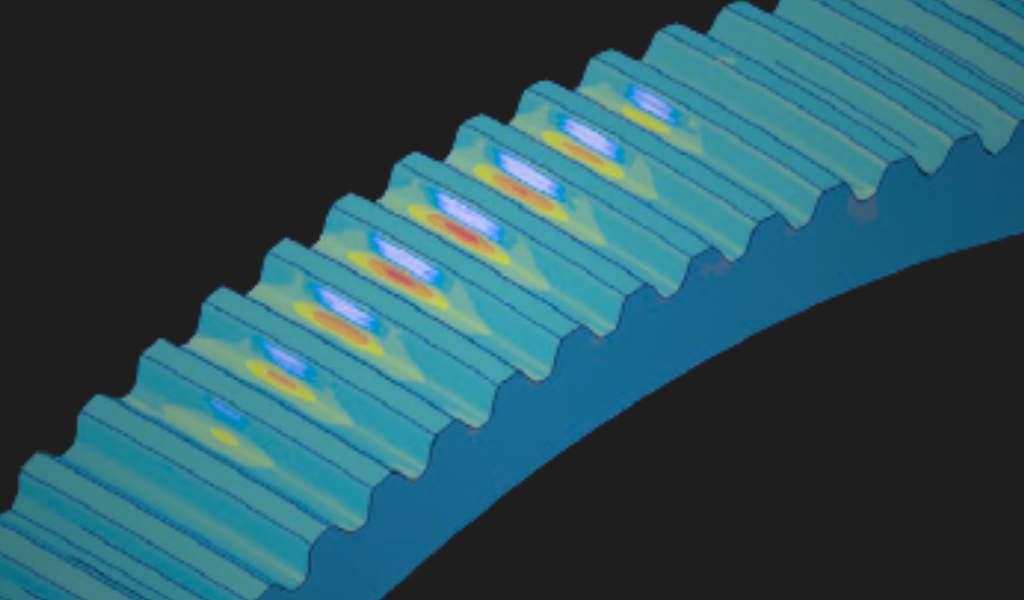

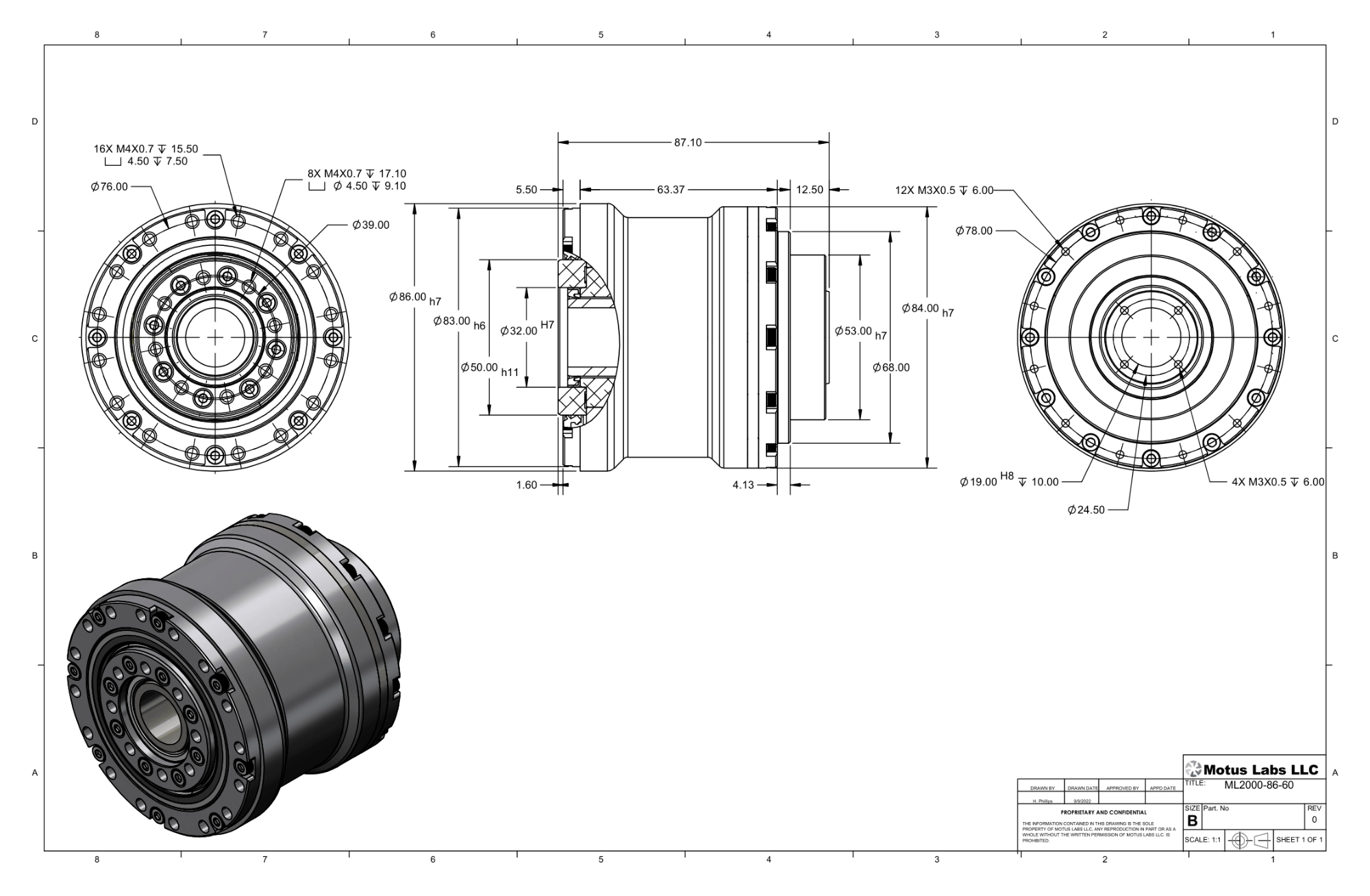

With the support of Hexagon and their simulation software Adams, Motus Labs was able to improve their design process, iterate faster, reduce the number of physical prototypes, and achieve their design requirements for a high-ratio robotic gear drive, ultimately leading to the successful launch of their ML2000 gear series.

Motus Labs Launches its Next Generation ML2000 Robotic Gear Series with Orbital Flex™

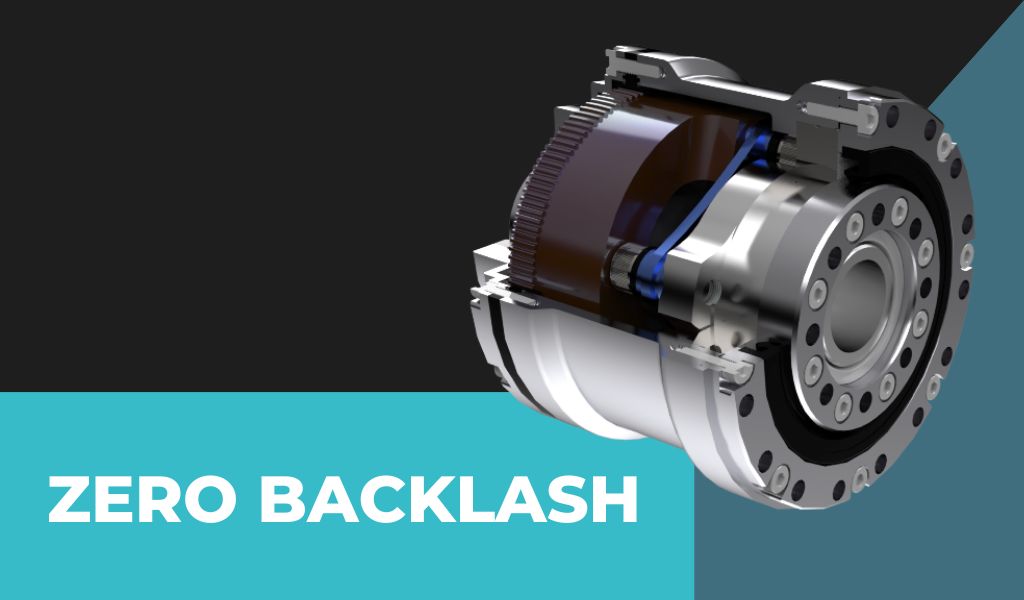

A High Torque, Zero Backlash Gear Solution NOT like anything else on the market.

The Evolution of the Robotic Joint and What We Can Expect Next

As we experience more advances in robotics, we look at how robotic joints are revolutionizing industries like manufacturing, science, and medicine, now and in the future.

Why is Backlash Important for Robotic Joint Performance and Safety?

When robotics companies are looking for gear solutions for their robotic arms, they will often hear the zero backlash claim. But what exactly does that mean and why is it important? There are very distinct reasons for gear solution providers to work towards zero backlash in their engineering and development efforts. What it means to […]

The Innovation Behind the Orbital Flex™ Gear Solution

Motus Labs was built around the concept of innovation in the robotic gear solutions space, and we’re constantly looking for ways to improve the customer experience and the performance of our robotic gears. This idea is even further supported by our recent gear solution design.

Motus Labs: The Evolution of the Robotic Joint

Every sci-fi movie or book set in the future speaks of robots taking over the world, or at least serving us our Sunday brunch. While we aren’t quite there yet, the future of robotics is already here and has been a big part of our labor force for some time now. How exactly did we […]

Unpacking Automate 2022: A First Year to Remember

The Motus Labs team has finally made it back to Texas and unpacked, in more ways than one, all the excitement from our week in Detroit at Automate 2022!

Experience the Innovation with Motus Labs at Automate 2022

Motus Labs is bringing robotics gear solutions innovation to Automate 2022, the conference where companies come together to showcase what’s possible in automation.

Five Ways to Capture More Value through Smarter Machine Design

VIDEO Recording | See how our partner, Guide Automation, shares simple tips, tricks, and strategies that will give you an edge in your next machine design. Increasing the overall value of your machine is often more effective than reducing the cost of components.