When robotics companies are looking for gear solutions for their robotic arms, they will often hear the zero backlash claim. But what exactly does that mean and why is it important? There are very distinct reasons for gear solution providers to work towards zero backlash in their engineering and development efforts.

What it means to have a zero backlash gear

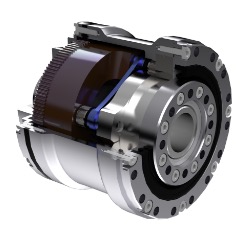

What exactly does it mean to have a zero backlash gear? First we have to look at the robotic gear and its mechanics. The gear is the element of the robotic arm that transmits power from the motor to the load of the arm and in turn increases the torque while reducing the speed to give the device its precision and control. It also ensures the safety of the arm which is pivotal when the robotic equipment is operating alongside human workers.

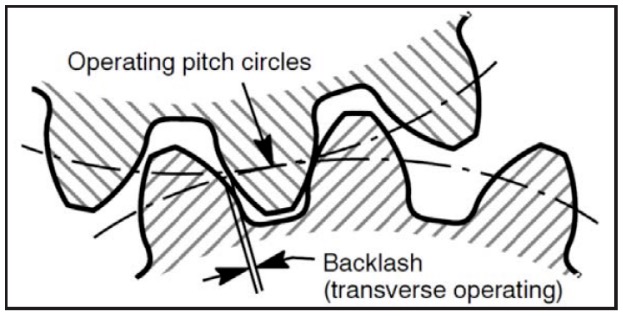

The backlash itself is caused by the opening between the edge of the tooth that transmits the power from the motor and the edge of the following tooth. This gap is a necessary element of the gears to be able to turn and if it didn’t exist the gearboxes would be made inoperable, but this function can also result in performance degradation. Other factors that can contribute to backlash, and reduced performance, are:

- Misalignments

- Small manufacturing inconsistencies

- Part tolerances

Why zero backlash is necessary

Zero backlash became critical based on the usage of the robotic gear and arm. And as robotic arms become more sophisticated in both their use and concurrent work with humans, mitigation of backlash becomes the top priority of gearbox engineers and manufacturers.

The operational reasons a gear might require zero backlash include:

- Rapid response time

- Required precision down to a few thousandths of an inch

- Move time tolerance of milliseconds

- Heightened levels of safety based on equipment proximities to human workers

Since we know backlash is a required component of a robotic gear, then how exactly do gear engineers develop a zero backlash gear?

How zero backlash in a robotic gear is achieved

Zero backlash is achieved in a number of ways but some of the more common include:

- Teeth tapering, where the teeth of the wheels are tapered to reduce backlash

- Preloading , which eliminates some of the space between the gear teeth with a spring

- Inserting a plastic filler, which fills the space causing the backlash

- Splitting the gear, which involves two halves of a gear running side-by-side with a spring between

Motus Labs Orbital Flex™ achieves zero backlash by preloading the rigid cup gear into the rigid stationary ring gear, providing the torque to the output. Maintaining a rigid preload at the tooth interface enables zero backlash while maintaining high rigidity, improving longevity of the ring gear and gear cup. To learn more about Orbital Flex™ please visit: The Innovation Behind the Orbital Flex™ Gear Solution – Motus Labs (motus-labs.com).