High Precision Gear solutions

High Torque with 10K hours

of Zero Backlash, under rated load.

Motus Labs designs and builds precision gear solutions for robotic and motion control applications to enable superior actuator performance.

Limited time offering**

ML2000-86-60 Try & Buy Program

Motus Labs is excited to announce the launch of our Try & Buy Program. This program allows you the opportunity to evaluate Motus Labs products, whether it’s to evaluate our new gearing capabilities or determine fit for an upcoming design, risk free.

No Upfront Payment

We understand time to review and evaluate new technology has additional costs associated with them. With our program, you can evaluate the ML2000-86-60 without any initial financial commitment.

60-Day Evaluation

You have a full 60 days to assess the performance of our ML2000-86-60 gear for future designs.

Flexible Return Policy

If, for any reason, you are unsatisfied with the gear performance within the 60-day evaluation period, contact your sales representative to set up your return at no cost.

** Limited time offering: The program is limited to two units per eligible customer.

ML2000 Gear Series

- High Torque

- High Rigidity

- High Positional Accuracy

- Integrated Cross Roller Output Bearing

- Linear Torsional Stiffness

All of this, while maintaining zero backlash for 10,000 hours.

Product overview

ML2000 Series

| ML2000-86 | ML2000-75 | ML2000-86 | ML2000-97 | ML2000-120 | |||

|---|---|---|---|---|---|---|---|

| Availability | Now | Q4 2024 | Q2 2024 | Q3 2024 | 2025 | ||

| Outer Diameter | 86 | 75 | 86 | 97 | 120 | ||

| Ratio | 60:1 | 100:1 | 100:1 | 100:1 | 100:1 | ||

| Rated Output Torque | 45 Nm | 20 Nm | 65 Nm | 130 Nm | 270 Nm | ||

| Repeatable Peak Output Torque ** | 75 Nm | 35 Nm | 90 Nm | 195 Nm | 400 Nm | ||

| Rated Input Speed ** | 2000 RPM | 2000 RPM | 2000 RPM | 2000 RPM | 2000 RPM | ||

| Repeatable Peak Input Speed ** | 4000 RPM | 4000 RPM | 4000 RPM | 4000 RPM | 4000 RPM | ||

| Efficiency ** | 64% | Coming Soon | Coming Soon | Coming Soon | Coming Soon | ||

| Backlash ** | 0 Arcsec | 0 Arcsec | 0 Arcsec | 0 Arcsec | 0 Arcsec | ||

| Torsional Stiffness | 7 Nm/Arcmin | 4 Nm/Arcmin | 7 Nm/Arcmin | 15 Nm/Arcmin | 30 Nm/Arcmin | ||

| Positional Accuracy (one way) | 2 Arcmin | 3Arcmin | 2 Arcmin | 2 Arcmin | 2 Arcmin | ||

| Noise *** | <70 dB | <70 dB | <70 dB | <70 dB | <70 dB |

** Under defined conditionals, *** Rated speed in ambient room

Want more information on how we test our gears?

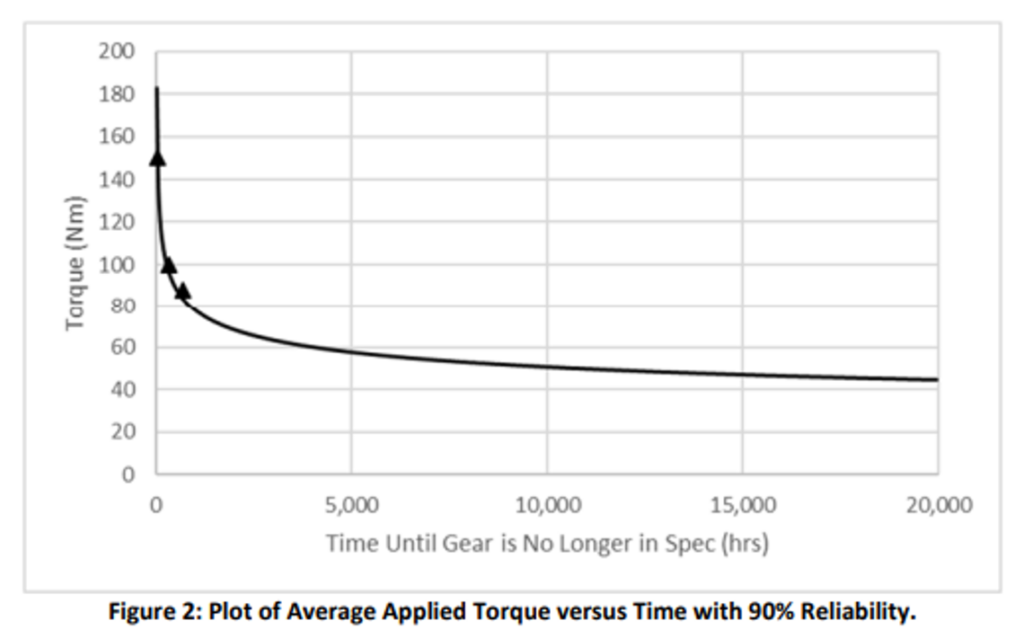

Unveiling Gear Consistency over 10,000 Hours

Explore Our Gear’s “Life Testing” Journey

Introducing the Orbital Flex™ gear design, a pioneering solution delivering high-torque capabilities and zero backlash, ensuring a maintenance-free, enduring gearbox.

Every endeavor marks its beginning and its conclusion. We’ve traversed through our degradation testing phase and are now embarking on our final leg: failure testing. To bolster our findings, we’ve enlisted the expertise of Stress Engineering Services INC., a trusted third-party entity, to validate our approach and results.

Discover the intricate details of our Life Testing Journey on our dedicated Testing Page.

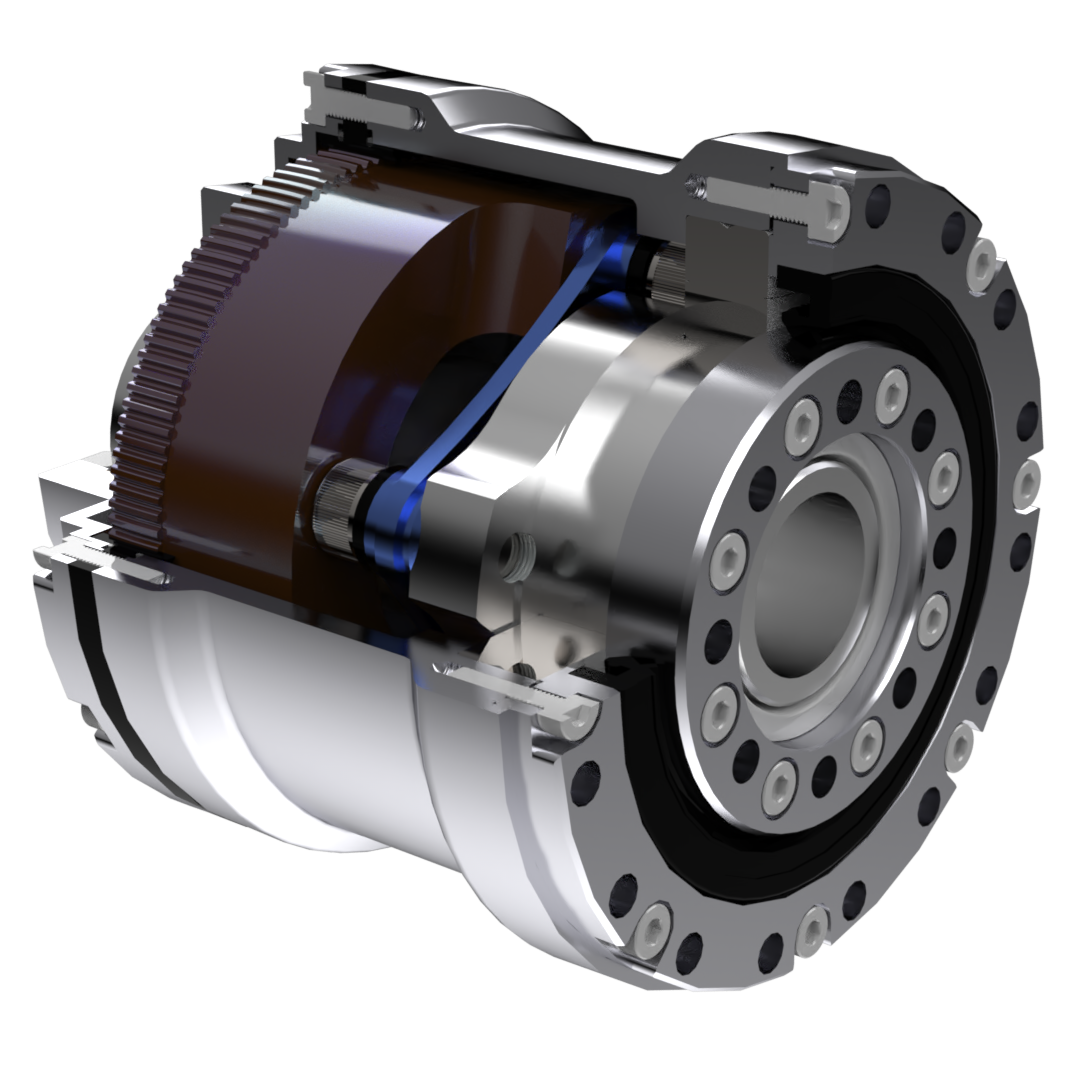

Orbital Flex™ Gear Design

Maintaining Zero Backlash for 10K Hours

Orbital Flex™, Motus Labs’ latest patented gear design, enables the ML2000 gear series to deliver zero backlash, linear torsional stiffness, and high load capacity.

The foundation of Orbital Flex™ is centered around a preloaded solid cup orbiting within a ring gear which generates high torque while enabling zero backlash and linear torsional stiffness. To offset the eccentric motion of the rigid cup, a compliance flexure is in place to transmit the high torque into a smooth output with high rigidity.

Orbital Flex™ is the gearing behind Motus Labs ML2000 gear series.

Featured Videos

ALL THE BUZZ AT AUTOMATE 2023

Next Generation ML2000 Gear Series

The ML2000 Gear series was built on a new gear design called Orbital Flex™ to specifically address the challenges of existing gear applications.

- FIRST new patented gear design offering accuracy and zero backlash in a maintenance free package

- ONLY design delivering zero backlash, high torque, high stiffness with no maintenance.

- BEST gear to enable use cases limited by traditional gear platforms

UNLIKE anything else in the market, focused on the robotic use cases of today and tomorrow